Стратегии по водосбережению для устойчивого развития

В условиях глобальной нехватки воды бытовым и промышленным потребителям необходимо внедрять эффективные методы сокращения потребления этого важнейшего из ресурсов.

Углекислый газ в двух словах

- На долю потребителей приходится около 10% воды, используемой во всем мире, а на долю промышленности — почти 20%. Среди последних наиболее востребованными являются термоэлектрическая энергетика, обрабатывающая промышленность, производство продуктов питания, горнодобывающая промышленность и добыча сырой нефти.

- Сокращение потребления воды имеет решающее значение для поддержки усилий по сохранению окружающей среды. Этого можно достичь с помощью таких методов, как оптимизация очистки промышленных и бытовых помещений, выбор водосберегающих материалов, устранение утечек, использование альтернативных технологий охлаждения и другие.

- Очистка и повторное использование промышленных сточных вод на предприятиях (например, для охлаждения) снижает зависимость от источников пресной воды.

- Экономия воды минимизирует воздействие на окружающую среду, сохраняет природные ресурсы, поддерживает корпоративные инициативы по устойчивому развитию и может снизить эксплуатационные расходы.

- Осуществляя инвентаризацию воды, модернизируя оборудование, внедряя методы повторного использования и сотрудничая с коллегами по отрасли, клиенты могут уменьшить затраты водных ресурсов.

Жизненная сила любого предприятия

Вода необходима каждому организму на планете Земля, ее называют жизненной силой планеты, и в некоторых регионах спрос на нее неуклонно превышает предложение. В то время как бытовое водопользование часто находится в центре внимания при обсуждении вопросов охраны окружающей среды, промышленный сектор несет ответственность за вдвое больший объем.

На этой странице представлен анализ использования воды, определены крупнейшие потребители, рассмотрены жизнеспособные стратегии водосбережения, проанализированы необходимые инвестиции и подчеркнуто влияние этих усилий на устойчивость.

Водопотребление по секторам

В разнообразном промышленном ландшафте основными потребителями являются:

- Термоэлектрическая генерация: Эта отрасль включает в себя угольные, атомные и газовые электростанции, на которые приходится примерно 45 % всего промышленного водопотребления, в значительной степени зависящего от воды для охлаждения.

- Производство: От водоемких процессов текстильного производства до сложных задач в производстве электронной техники — этот сектор сильно зависит от воды для промывки, ополаскивания, разбавления, охлаждения и транспортировки материалов.

- Производство продуктов питания и напитков: Путь «с грядки на стол» требует значительных затрат воды, причем не только на аграрных полях, где выращиваются продукты питания. Вода требуется для переработки сырья и очистки оборудования, а зачастую и для непосредственного использования в продукции — все это вносит свой вклад в затраты водных ресурсов в производстве.

- Горная промышленность: Добыча полезных ископаемых требует интенсивного использования воды для различных работ, включая пылеудаление, транспортировку шлама и разделение минералов.

- Нефть и газ: Добыча ископаемого топлива, особенно такими методами, как гидроразрыв пласта, требует значительных объемов воды.

Результаты анализа

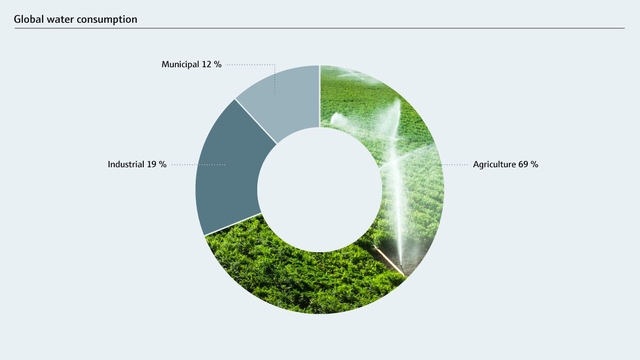

На сельское хозяйство приходится 70% мирового потребления воды, на промышленность — 20%, а на бытовые нужды — оставшиеся 10%.

Статистика использования воды в этих отраслях может удивить. Например, для выработки одного МВт-ч электроэнергии, достаточной для питания примерно 1000 домов в течение часа, требуется от 11 500 до 75 700 литров (от 3000 до 20 000 галлонов) воды в зависимости от источника энергии.

Производство предметов повседневного спроса также сопряжено со скрытыми затратами на воду. Например, на производство одной хлопковой футболки расходуется примерно 2 700 литров (700 галлонов) воды . Эти цифры отражают потенциальное влияние даже процентного сокращения на общее количество потребляемой воды.

Результаты анализа

На производство одной хлопковой футболки уходит примерно 2 700 литров (700 галлонов) воды.

К счастью, в настоящее время разрабатывается целый ряд стратегий экономии воды, которые можно реализовать без ущерба для производительности и качества работы. В целом они делятся на два типа: сокращение потребления и повторное использование воды.

Снижение потребления

Подобно тому, как люди пытаются добиться эффективности процессов в других областях (например, сократить потребление энергии и использование дорогостоящих химикатов), минимизация потребления воды также имеет решающее значение для бытового и промышленного применения. В быту это достижимо за счет внедрения водосберегающих приборов и строгого ограничения ручного использования воды, например, для приготовления пищи, уборки, полива растений и купания. Для промышленности это достигается путем установки водосберегающего оборудования и проведения тщательной инвентаризации для выявления областей, в которых необходимо сократить объемы производства.

Оптимизация процедуры очистки

В различных отраслях промышленности производственные объекты требуют периодической очистки технологического оборудования. Производители могут оптимизировать время этих циклов, используя датчики, которые определяют идеальную продолжительность, чтобы избежать чрезмерной очистки.

Кроме того, многие современные программные платформы для управления предприятием оснащены возможностями прогнозного моделирования, которые поддерживают методы оптимизации для минимизации затрат и ресурсов, включая потребление воды. При использовании этих моделей для регулировки различных параметров технологического процесса можно эффективно снизить потребление воды, помогая производителям определить оптимальные рабочие значения, сохраняя при этом качество продукции и соответствие нормативным требованиям.

Идеальный подбор материала

Выбор, сделанный на ранних этапах производства, может оказать влияние на потребление воды. Выбор материалов, которые требуют меньше воды для обработки, например, переработанных материалов или материалов с менее водоемкими методами производства, может способствовать общей экономии воды во всей логистической цепочке.

Обнаружение и устранение утечек

Несмотря на кажущуюся простоту, часто на обнаружение и устранение утечек не обращают внимания как в быту, так и в промышленном секторе. Выполнение таких задач, особенно при наличии разветвленной трубопроводной инфраструктуры, позволяет предотвратить значительные потери воды, которые обходятся недешево. Регулярный осмотр систем и своевременный ремонт помогут сэкономить расход воды и последующие расходы.

Альтернативные технологии охлаждения

Зависимость от воды для охлаждения в электрогенерации и других отраслях промышленности стимулирует инновации в области разработки альтернативных методов охлаждения. Например, воздушное охлаждение и гибридные системы охлаждения позволяют существенно снизить потребление воды и минимизировать сброс нагретой воды в окружающую среду.

Повторное использование воды

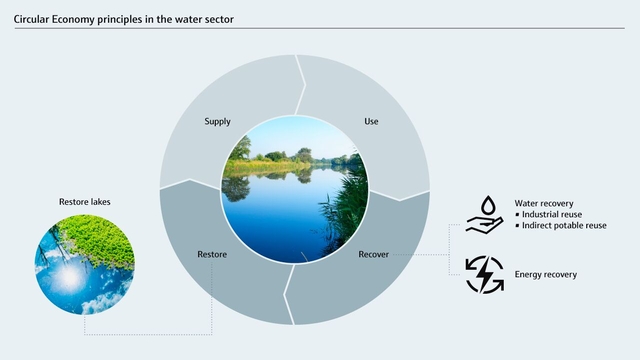

Помимо описанных ранее методов прямого сокращения потребления водных ресурсов, методики повторного использования воды становятся все более распространенными на региональном уровне среди жителей городов и даже в рамках отдельных промышленных предприятий. Повторное использование воды эффективно увеличивает ее пользу, позволяя потребителям использовать одну и ту же воду несколько раз, что, в свою очередь, приводит к общему сокращению расходов.

В сфере промышленности рекуперация и очистка технологических сточных вод представляет собой устойчивую альтернативу забору пресной воды для многих областей применения. В зависимости от сферы применения могут возникать проблемы с регулированием, но системы замкнутого цикла промышленного водоснабжения, в которых вода используется повторно, а не утилизируется, находят все большее применение. Например, охлаждающая вода на электростанциях, которая часто сливается в реки под действием высоких температур, может быть очищена и повторно использована в пределах станции или даже переработана для других целей, как промышленных, так и сельскохозяйственных.

Экономические инвестиции, необходимые для реализации этих стратегий сохранения, варьируются в зависимости от конкретных технологий, масштабов внедрения и существующей инфраструктуры. Хотя для повторного использования воды требуются первоначальные инвестиции в создание систем сбора и очистки, они часто приводят к долгосрочной экономии средств в дополнение к преимуществам устойчивого развития. Это произошло в основном благодаря сокращению забора воды и снижению платы за утилизацию сточных вод.

Пять шагов для экономии воды

В эпоху роста информационной прозрачности и взаимодействия с заинтересованными сторонами сохранение водных ресурсов свидетельствует о социальной ответственности и бережном отношении к окружающей среде. Такие действия могут привлечь заинтересованные стороны, которые придают большое значение устойчивому развитию, и найти отклик у потребителей, которые более склонны принимать решения о покупке, основываясь на экологических показателях компаний.

Чтобы снизить потребление пресной воды и добиться положительного экологического эффекта, в промышленности можно реализовать следующие пять шагов:

- Проведение проверку эффективности использования воды: начните с анализа операций, где расходуется больше всего воды. Затем оцените её использование, возможность утечки и повторного использования.

- Устранение неисправности: устраняйте утечки и неисправности оборудования, которое расходует воду, и продолжайте следить за её использованием и выявлять области, где требуется улучшение.

- Внедрите практики повторного использования воды: рециркуляция воды в производственных процессах, где это возможно, или внутри предприятия в системе замкнутого цикла. Очистка сточных вод для повторного использования в непитьевых целях, например, для охлаждения и орошения.

- Модернизация неэффективного оборудования: изучение и установка инновационного водосберегающего оборудования для снижения потребления.

- Сотрудничество с коллегами по отрасли: участвуйте в общеотраслевых обсуждениях и инициативах по экономии воды, используя для этого государственные льготы и финансовую помощь.

Бытовые пользователи могут применять аналогичные стратегии экономии воды в повседневной жизни, поэтому тем, кто не связан с промышленными предприятиями, важно не упускать из виду эти методы.

Примеры сохранения

Следующие примеры демонстрируют меры по сохранению окружающей среды, которые применяются в конкретных отраслях промышленности:

- Производство: внедрение водоэффективных систем охлаждения, повторное использование технической воды и оптимизация процессов очистки.

- Продукты питания и напитки: внедрение водосберегающих технологий производства продуктов питания, сокращение использования воды при очистке и повторное использование очищенных сточных вод для орошения.

- Производство электроэнергии: внедрение передовых технологий охлаждения, оптимизация циркуляции воды в системах охлаждения и повторное использование промышленных сточных вод для непитьевых целей.

Применяя эти подходы, промышленные предприятия могут сократить потребление воды, снизить эксплуатационные расходы и внести свой вклад в обеспечение экологически рационального использования водных ресурсов.

Устойчивость и экономические последствия

Сокращение забора воды из рек, озер и водоносных горизонтов помогает сохранить хрупкий баланс водных экосистем, поддерживает сохранение биологического разнообразия и сохраняет эти жизненно важные природные ресурсы для будущих поколений. Оптимизация процессов также может помочь компаниям сэкономить деньги.

Помимо того, что сохранение воды способствует сбережению самого жизненно важного ресурса, оно также напрямую снижает углеродный след, поскольку сокращает потребность в очистке и распределении воды, для которых требуется много энергии.

Сохранение водных ресурсов — важнейшая экологическая и стратегическая экономическая возможность со значительными социальными выгодами. Внедрение инновационных технологий, эффективные процессы и повторное использование воды позволяют сократить потребление, что соответствует глобальным усилиям по бережному отношению к природным ресурсам.